Regular Slotted Containers

This is the most popular box type; usually with the longer flaps meeting at the center of the box when closed. Regular slotted containers are suited to large scale manufacturing but are also perfect for shipping and storing small individual items.

Half Slotted Containers

Half slotted containers only have one set of flaps and can be used as a top or bottom to cover or enclose items. The opposite side of the box is open, which allows it to slide over an item. This style is ideal for transport and storage of all sizes of items.

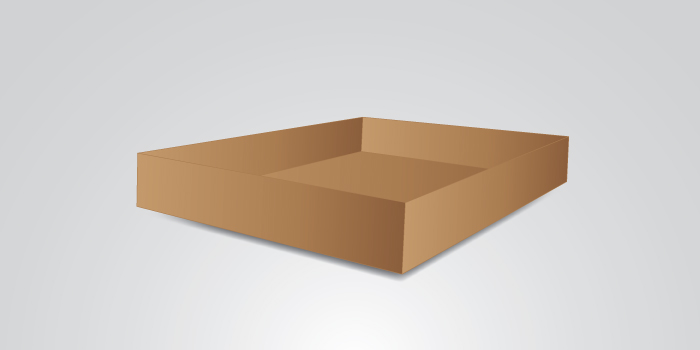

Slotted Trays

These are corrugated trays that can be used to hold a range of items. Commonly found in the food and beverage industry for products such as bottled water, soft drinks, snack foods, and other packaged foods.

Self-Locking

These are boxes that need to be assembled and are ideal for shipping a full range of items.

Box & Lid

This is a common format where additional stacking strength is required to protect items.

Corrugated Board Strength

Board strength used should consider all the factors that define how strong the box should be. There are a number of questions you must ask yourself before you can accurately assess how strong a particular box should be, such as:

- The nature of the products being packaged

- The total weight of the box

- The size of the box

- How the cardboard box will be stacked, stored, and transported.

CPI has a very experienced team throughout the organization that understands the local corrugated market and has productive working relationships at many levels throughout our customer base. Contact us for assistance with the right corrugated board to meet your business needs.

Corrugated Box Construction and Flute Types

Corrugated Flutes are the S shaped waves/arches of a corrugated box that makes up the board, and are essentially the reinforcement that make up the board. They run parallel to the height of the container and give it its rigidity and crushing/stacking strength. As well as providing stacking strength, flutes also provide insulation that protects products from sudden temperature changes.

Generally speaking, larger flute profiles provide greater strength and cushioning, while smaller flute profiles provide better printability and foldability.C flutes provide good cushioning, stacking and printing properties. Ideally used for glass, furniture and dairy.

- C flutes provide good cushioning, stacking and printing properties. Ideally used for glass, furniture and dairy.

- B flutes provide good stacking strength and crushing resistance. Ideally used for canned goods and displays.

- E flutes provide a super printing surface which makes it an excellent choice for die-cut custom boxes, and because it is very thin it reduces size and save storage space.

CPI provides you with the option of choosing between single and double-wall cardboard construction. Single Wall is the most common corrugation material – it simply consists of 1 layer of whatever flute type you choose.

Double Wall construction, also known as ‘heavy duty’ corrugation material is used for heavy or large objects. A Double wall consists of 2 layers of flutes, usually 1 layer of B and 1 layer of C.